A OPTIMISM FOR THE FUTURE OF SAWN TIMBER PRODUCTS Page 10

MAGAZINE PUBLISHED BY SMÅLANDSHAMNAR AB BUILDING LOGISTICS FOR GREEN ENERGY Page 15

HISTORIC PORT WITH AN IDEAL LOCATION

PORT OPERATIONS IN STEP WITH THE TIMES

UNIFIED EXPERTISE IN CARGO HANDLING Page 9

SUSTAINABILITY IN ALL AREAS

DRIVING FORCE FOR THE ENTIRE REGION

OSKARSHAMN

Telephone: 010-356 39 00

Mailing address: Norra Strandgatan 50, 572 32 Oskarshamn

Visiting address: Norra Strandgatan 50, Oskarshamn

E-mail: info@smalandshamnar.com

Web page: www.smalandshamnar.com

VÄSTERVIK

Telephone: 010-356 39 00

Mailing address: Norra Strandgatan 50, 572 32 Oskarshamn

Visiting address: Färjevägen 10, Västervik

E-mail: info@smalandshamnar.com

Web page: www.smalandshamnar.com

Production www.krepart.se Photo Curt-Robert Lindqvist Print V-TAB, 2024/03

VÄSTERVIK 2

OSKARSHAMN

THE CONDITIONS FOR DEVELOPMENT

Development trends are pointing straight up. In recent years, all Smålandshamnar’s areas of operation have grown steadily.

For CEO, Niclas Strömqvist, it has been a revolutionary time. He took on his role in the middle of the pandemic with everything it meant from a business perspective.

Nevertheless, together with his employees, he has been able to keep up the positive development with an increased turnover and continued good profitability.

wood products with both experienced and competent personnel and a bespoke machinery. We want to be at the forefront of all destinations for timber and forest products.”

“WE GROW FOR AND WITH OUR CUSTOMERS.”

“We grow for and with our customers. By meeting customers’ logistics needs and delivering quality services, we not only ensure satisfied customers, we also create a positive environment for all parties – the customers, their customers, the region and our employees,” he says.

Breaking records

Since the beginning of the 20s, all business areas within Smålandshamnar’s operations have developed positively. Timber handling is expected to break records in 2024.

“For a long time, we have adapted our operations for handling and shipping sawn

Logistics link Niclas Strömqvist also highlights the terminal handling operations, responsible for Scania’s packaging pool, ferry traffic and the cooperation with Destination Gotland and any future destinations, as well as the company’s development towards becoming a nationally important project and service port and logistics link for both onshore and offshore wind power.

By actively monitoring the external environment and creating even better conditions for future shipping and logistics, Smålandshamnar is looking ahead.

“The future looks positive and our goal is to continue our growth and be a driving force for the entire development of Oskarshamn. The focus is always on ecological, social and economic sustainability,” emphasises Niclas.

3

PORT OPERATIONS STEEPED IN TRADITION

The business started in the 1860s and is today known as Smålandshamnar. Since then, a lot has happened and the port operations have grown and developed.

The origin of the port in Oskarshamn came about due to Döderhultsviken’s naturally favourable conditions with a well-sheltered position and good depths.

The southern part of the port was originally bordered by steep cliffs that fell into the sea. In the 1800s, fillings were made to create the South quay and the current Skeppsbron. However, the quay infrastructure was insufficient, resulting in the construction of the North quay starting around the turn of the last century.

1860

the first port management is formed.

1992

the complete port and cargo management in Västervik is taken over.

1875

mail and passenger transport starts from Oskarshamn to Visby.

1993

the name is changed from Oskarshamns Hamn AB to Smålandshamnar AB.

1900

construction of the North quay begins.

1929

the current company is registered as AB Oskarshamns Stuverikontor. The main customers at the port subscribe for the shares.

2001

management of the Västervik terminal is returned to Västervik municipality.

2003

the business is renamed Oskarshamns Hamn AB.

1961

the oil port is completed with a quay, oil tanks and pipelines.

2010

the Ocean quay is extended by an additional 130 metres to a total length of 480 metres.

4

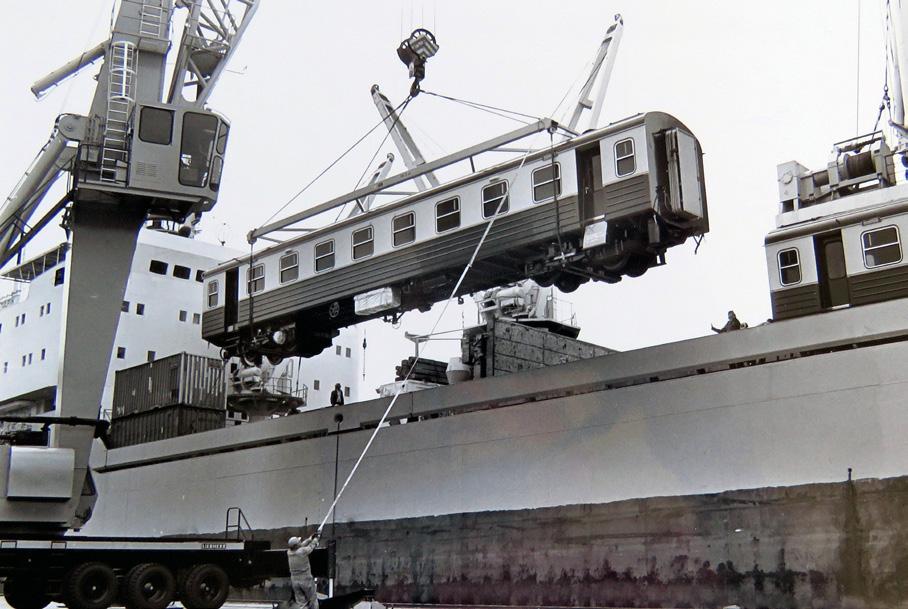

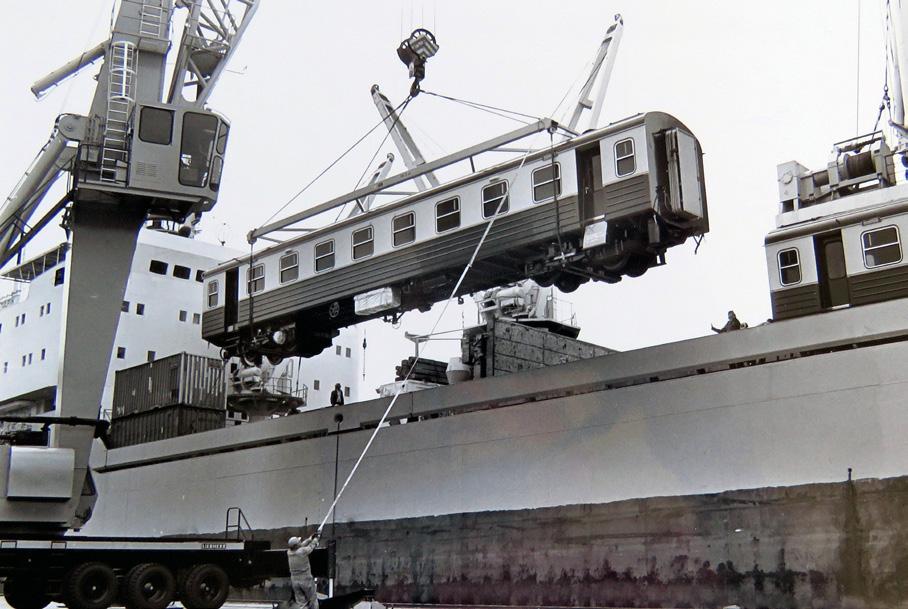

1959

1977

1973

the current ferry site for Gotlandstrafiken is completed.

1976

Oskarshamn municipality acquires 49.9% of the shares in AB Oskarshamns Stuverikontor. The purpose is to coordinate the port and stevedoring operations to make better use of resources.

2016

Västerviks Logistik och Industri AB, which operates port operations in Västervik, is acquired and the company’s name changed to Smålandshamnar AB.

1980

Hamnens Hus is ready to move into.

2017

Smålandshamnar AB and Västerviks Logistik och Industri AB are merged at the beginning of the year. Operations in the Port of Västervik are now run by Smålandshamnar AB.

1987

the Ocean quay is completed.

1983 a new organisation is formed from the port and stevedoring operations. The name is changed to Oskarshamns Hamn AB. The new company is to run the entire port operations.

2020

Smålandshamnar AB takes over Scania’s packaging pool.

2022

Smålandshamnar AB receives the Industry Winner 2022 award based on positive results and remaining in the black for the past seven years, among other things.

5

The ship Border Sentinel in the oil port in 1961.

1960

1986

Photo Oskarshamn municipality’s image archive, Smålandshamnar AB and the Maritime Association’s image archive

COMBINED TERMINAL AND CARGO HANDLING

Smålandshamnar has built up extensive expertise and experience in terminal and cargo handling services. The aim is to expand operations even further.

Melissa Johansson has worked with terminal and cargo handling at Smålandshamnar since 2020. Together with her employees, she receives around 40 trucks every day for unloading and loading. More than half of all transport operations are down to the dedicated collaboration with Scania and the management of their packaging pool.

“I previously worked at Scania and came to Smålandshamnar as part of the outsourcing and centralising of their packaging operations. With the whole of the operations brought under our roof, we have a better overview and can work more efficiently,” she explains.

25,000 square meters

unloading trucks, terminal handling also includes rail freight. In addition, Smålandshamnar also offers ancillary services such as warehouse administration and the letting of warehouses.

Melissa Johansson

Melissa Johansson

”Today, we have three buildings for warehousing and a tent for handling goods for Scania’s packaging pool. It’s all about stacking carefully and creating the right space to accommodate all the packaging material that needs to be handled, stored and then transferred on again,” explains Melissa. In addition to handling Scania’s empty packaging, Smålandshamnar also repairs pallets and handles empty containers from Scania’s operations in Brazil.

For a long time now, Smålandshamnar has had a strong tradition of terminal and cargo handling services, focusing on pallet and reel handling. In addition to loading and

“We have built up a wealth of knowledge of both goods receipt and terminal handling. We actually only need more space and better infrastructure to be able to expand operations further,” emphasises Melissa.

Smålandshamnar also offers cargo handling services quayside, including loading and unloading vessels and transport to warehouses.

6

SAFEGUARDING FERRY TRAFFIC

Daily calls all year round. Approximately 500,000 passengers and other cargo are transported each year on Destination Gotland’s scheduled ferry crossings between Oskarshamn and Visby.

The summer months are hectic, to say the least, for quay foreman, Torbjörn Krafft, and his coworkers from Smålandshamnar. They are responsible for all the loading and unloading of trucks and cargo transport vehicles as well as the directing of passenger cars.

“During the peak season in the summer months, the car decks are usually full. This means around 400 cars have to be driven off and then the same number driven on at each call. In the summer, Destination Gotland’s vessels also take the opportunity to fill their water tanks when docked in Oskarshamn, since there is a shortage of drinking water in Visby,” explains Torbjörn.

Maintenance of the quay

Unlike in the summer, cargo transport makes up most of the traffic that has to be handled and placed on the vessel correctly with regards to weight by Smålandshamnar’s personnel in the winter.

We are also responsible for all types of maintenance concerning the quay. This includes everything from cleaning and clearing of snow to maintaining the gangway and repairs to the quay infrastructure itself.

During the winter months, Destination Gotland operates the line to Oskarshamn with one departure a day. During the summer season, there are three departures a day three days a week and two departures a day on the other days. The future forecast is for the demand for passenger transport to

increase between Oskarshamn and Visby with additional calls.

The current agreement on ferry traffic to Gotland runs until 2027. As one of Smålandshamnar’s largest business areas and an important industry for the entire Oskarshamn area, there is high hope that the agreement will be renewed and extended.

“Meeting future needs will certainly require some investment in both the quay infrastructure and other equipment. What’s more, the ferry link to Gotland is important for the entire region. We also have extensive experience and expertise in cargo handling and loading and unloading operations,” says Torbjörn

During the summer, there is also a ferry link to Byxelkrok on Öland with several daily departures from the inner harbour in Oskarshamn. Smålandshamnar’s future visions also include plans for a ferry line to the Baltic region.

7

Torbjörn Krafft

8

TRADITION OF SAWN WOOD PRODUCTS

One of Sweden’s leading export ports for sawn wood products. Smålandshamnar continues to manage and develop its proud tradition of cargo and, in particular, timber handling.

For a long time, Smålandshamnar has adapted its operations for handling and shipping sawn wood products with experienced and competent personnel and bespoke machinery.

Quay foreman, Pär Larsson, started working as an hourlypaid employee at Smålandshamnar back in 1983 and has seen the cargo handling business develop continuously and steadily.

“The rate at which we can handle timber in particular is significantly higher and more efficient today. There are never fewer than four parcels of timber being loaded or unloaded at the same time,” he explains.

Increase exports

Sawn wood products are the largest single type of cargo handled by Smålandshamnar and overseas exports are mainly concentrated around North Africa. With the entire sawmill industry in southern Sweden as a potential customer, Smålandshamnar has an express aim to further increase exports of sawn wood products in the long term.

“Depending on how future demand develops, we are looking at the UK and US, for example.”

Pär notes that, in recent years, major increases in the shipment of sawn wood products have clearly shown that there is both the capacity and expertise at Smålandshamnar for future expansion.

“With our experienced personnel and adapted equipment, as well as our strategic location, Smålandshamnar is definitely securing its position as one of Sweden’s leading export ports for sawn wood products,” he says.

Queue into the area

The number of other types of cargo passing through the port is also steadily increasing. This includes paper and pulp, timber and pulp wood, and bulk goods.

Sometimes there may be a queue of timber trucks entering the port area to be unloaded for onward transportation. We also receive large quantities of pulp in bales that are temporarily stored before they are transported on to the various mills in Småland. We have lots of future opportunities for expanding our handling of all types of goods,” emphasises Pär.

9

Pär Larsson

WIND POWER THE RIGHT PLACE FOR

In the right place for the future energy transition. Smålandshamnar is both strategically located and has the capacity as a logistics link for both offshore and onshore wind power.

The gigantic rotor blades in the harbour yard are proof. Being able to handle the bulky wind turbine components requires space, the equipment and knowhow.

“We’ve learned over time. For a logistics process to work, the various components have to be set up and sorted in a certain order. Otherwise, there will be problems when they are collected and transported to the sites where they are assembled,” explains Robert Bladström.

He is a team leader in Smålandshamnar’s stevedoring operations and has mainly worked with handling wind power components since operations properly got under way in around 2020. Smålandshamnar is one of the most ideally located logistics links for the expansion of both offshore and onshore wind power in southern Sweden.

“On the one hand, we have the ability and capacity to receive, unload, dismantle and store the wind power components that come by ship from China, Vietnam, Spain and other places. And on the other, we are perfectly placed for loading and onward transportation to the wind farms up and running or planned around southeast Sweden,” says Robert.

Big potential

So far, the business has mainly focused on onshore wind power components. But Smålandshamnar also has great future potential as a project and service port, as well as a logistics link for the large offshore wind power projects planned in the southern Baltic.

“We have recently invested in a hook machine, specially adapted for handling wind power components in the port. Offshore wind power is certainly more volumeintensive. But we are adapting ourselves for new consignments,” says Robert.

Smålandshamnar has also trained its personnel and obtained the certifications that are crucial for working with clients both nationally and internationally.

10

Robert Bladström

“we have the capacity to receive, unload, dismantle and store the wind power components.”

11

STRONGER LINKS BETWEEN

LAND AND SEA

The aim is to create an even clearer link between land and sea. We will achieve this by developing and adapting Smålandshamnar’s port and terminal facilities as well as improving accessibility and infrastructure.

The steady expansion of both offshore and onshore wind power in recent years has meant that Smålandshamnar is already one of the most important logistics links in southern Sweden for shipping, storing and servicing wind power components.

The shipping and handling of sawn wood products is also expected to reach record levels in the coming years. Smålandshamnar’s goal is to be at the forefront as a shipping port to all major destinations around the world.

Smålandshamnar also has a clear ambition to develop and expand its strong tradition of terminal and cargo handling services further in cooperation with the business community, both locally and regionally.

Future shipping Ferry traffic, which currently operates between Gotland and Öland, has great potential for future development. Smålandshamnar is looking at the Baltic countries as new future destinations for ferry lines from Oskarshamn.

“This means that Smålandshamnar will need to be developed in several areas in the future. Both the port and terminal facilities need to be adapted for future operations. We also need to increase port accessibility and infrastructure sustainably. Achieving this requires close cooperation with both the municipality and the business community in the region,” says CEO, Niclas Strömqvist.

The first subgoal of Smålandshamnar’s future vision is to prepare the outer harbour for future shipping. This includes further

expanding the area for handling and storing wind power components and preparing to move scrap handling out of the inner harbour.

Expansion

The next step involves realising a new pier east of the Ocean quay – Grimskallen – in order to expand the port’s logistics services for wind power. As part of this extension, a recreational area will also be built, both to reduce noise and to create a new meeting place with the sea for both the local population and visitors.

“SMÅLANDSHAMNAR IS A DRIVING FORCE BEHIND THE DEVELOPMENT OF THE ENTIRE MUNICIPALITY.”

“We have set ambitious goals and to achieve them, we need to further increase our use of resources, actively monitor the external environment and work closely with society in general. By creating clearer links between land and sea also means that Smålandshamnar is a driving force behind the development of the entire municipality,” stresses Niclas.

12

Niclas Strömqvist

13

Vision 2040

Kolberga quay

Ocean quay 2023

14

SUSTAINABILITY ADAPTING TO

The underlying focus for the future development of Smålandshamnar is sustainability on both the large and small scale. It involves both environmentally adapting operations as well as acting as a sustainability hub by refuelling with climate-adapted fuels for different modes of transport.

To reduce the impact on the external environment from its noise, emissions, waste, chemicals and energy consumption, Smålandshamnar has been working actively when it comes to the climate, environment and sustainability.

“This includes taking part in a preliminary study project aimed at making Smålandshamnar’s operations 90 percent fossilfree over the coming years,” explains CEO, Niclas Strömqvist.

We will achieve this mainly by electrifying our own machinery as much as possible as well as making new investments. The larger terminal buildings will also be equipped with solar panels.

“In cases where it is not possible to replace cranes and machines with similar electric ones for various reasons, we will look at different hybrid variants to minimise our own emissions and environmental impact.”

“For our future development, it is important to be able to meet both the need for fossilfree refuelling and electrical charging,” stresses Niclas.

Stable employer

Ensuring that both ecological as well as economic and social sustainability work together and develop in symbiosis is vitally important for Smålandshamnar’s future work. The social sustainability goals include being a safe and stable employer and workplace.

“The personnel are our most important resource and the foundation for Smålandshamnar’s high level of expertise. Our sustainability work is extremely important for being able to recruit a competent workforce in the future as well.

“SMÅLANDSHAMNAR’S OPERATIONS WILL BE 90 PERCENT FOSSIL-FREE IN THE COMING YEARS.”

Natural gas and biogas Niclas Strömqvist points out that port operations in general have come a long way in adapting to the climate and sustainability. One element of Smålandshamnar’s future sustainability work is to create a hub for climateadapted fuels, aimed at many different modes of transport.

“A total of around 60,000 heavy transport vessels pass through our operations annually. The aim is, together with the municipality, to be able to offer refuelling with natural gas (LNG) and biogas (LBG).”

Smålandshamnar’s ambition in the early stages is also to be the Baltic Sea port that can offer gas refuelling to incoming vessels. It also wants to be able to offer vessels an electrical connection for refuelling while docked.

Smålandshamnar is certified to ISO 14001, ISO 9001 and ISO 45001, which also supports environmental and sustainability work going forward.”

15

ON THE RIGHT COURSE FOR THE FUTURE

Executive team of Smålandshamnar: Anders Randow, Chief technology officer, Stefan Gustafsson, Chief security officer, Emma Jörnling, Chief financial officer, Niclas Strömqvist, Chief executive officer, and Timmy Randow, Production manager.

OSKARSHAMN

OSKARSHAMN & VÄSTERVIK

Telephone: 010-356 39 00

Mailing address: Norra Strandgatan 50, 572 32 Oskarshamn

Visiting address: Norra Strandgatan 50, Oskarshamn

Visiting address: Färjevägen 10, Västervik

E-mail: info@smalandshamnar.com

Web page: www.smalandshamnar.com

GÖTEBORG

MALMÖ

VÄSTERVIK

Melissa Johansson

Melissa Johansson